How much do fins flex during surfing?

A few weeks back, we covered the German study that measured pressure on fins during surfing, recording up to 300 N of force creating lift during turns. But knowing the pressure acting on fins doesn’t tell us what happens to the fins themselves under those loads. Computational models can predict deformation, and lab tests can measure it under controlled conditions, but until recently, nobody had measured fin flex during actual surfing.

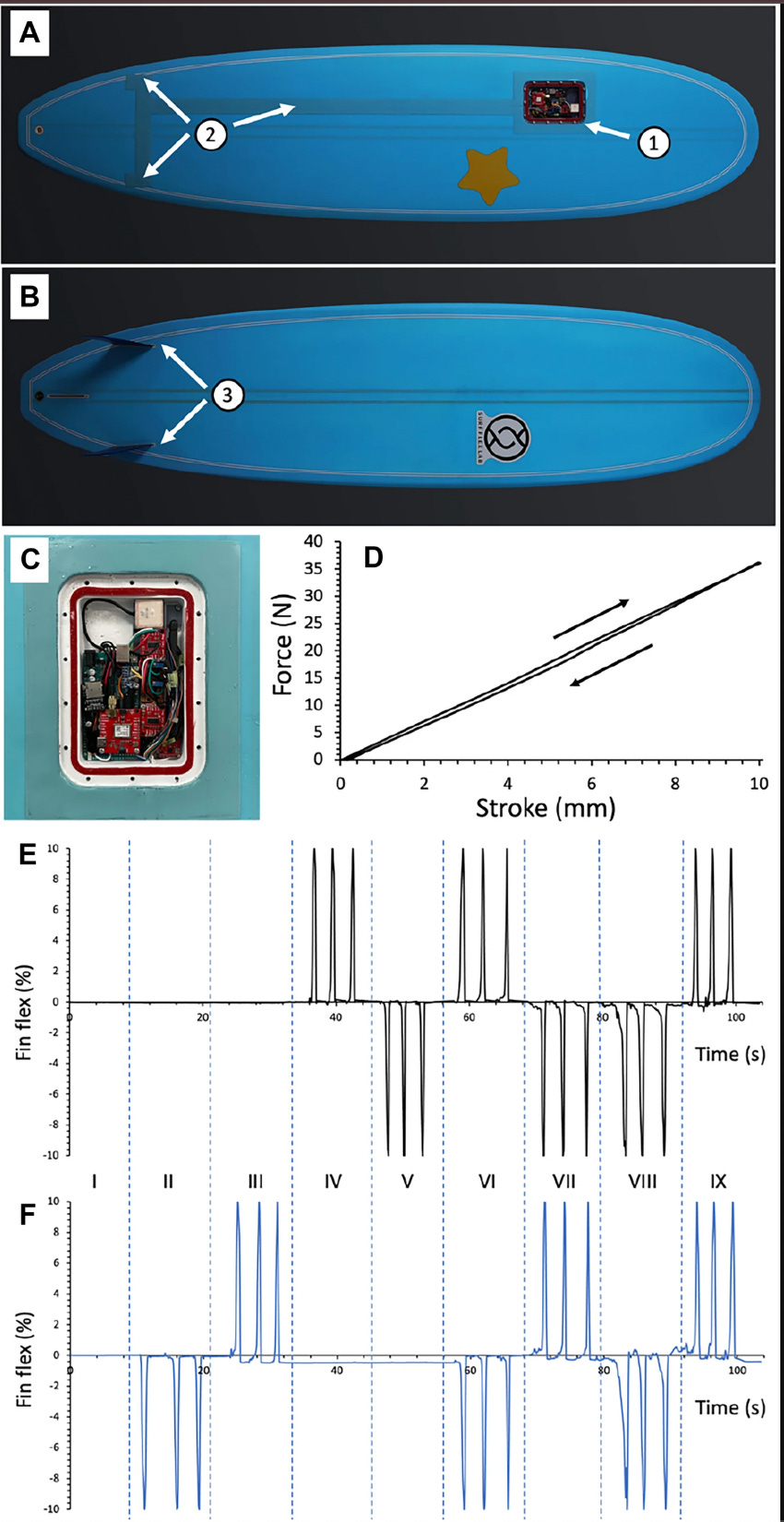

Pawel Krzyzanowski and Marc in het Panhuis out of the appropriately-named Surf Flex Lab at the University of Wollongong set out to change that. They custom-fitted a 7’4”, 51L surfboard with an embedded measurement system consisting of GPS, accelerometers, and a gyroscope collecting data 80 times per second. They 3D-printed a pair of twins modeled on the Futures T1, pausing the printing midway to embed commercial Wheatstone bridge strain gauges inside each fin. The sensors connected via computer data cables running through channels routed into the board, all sealed in an acrylic box with a silicone gasket

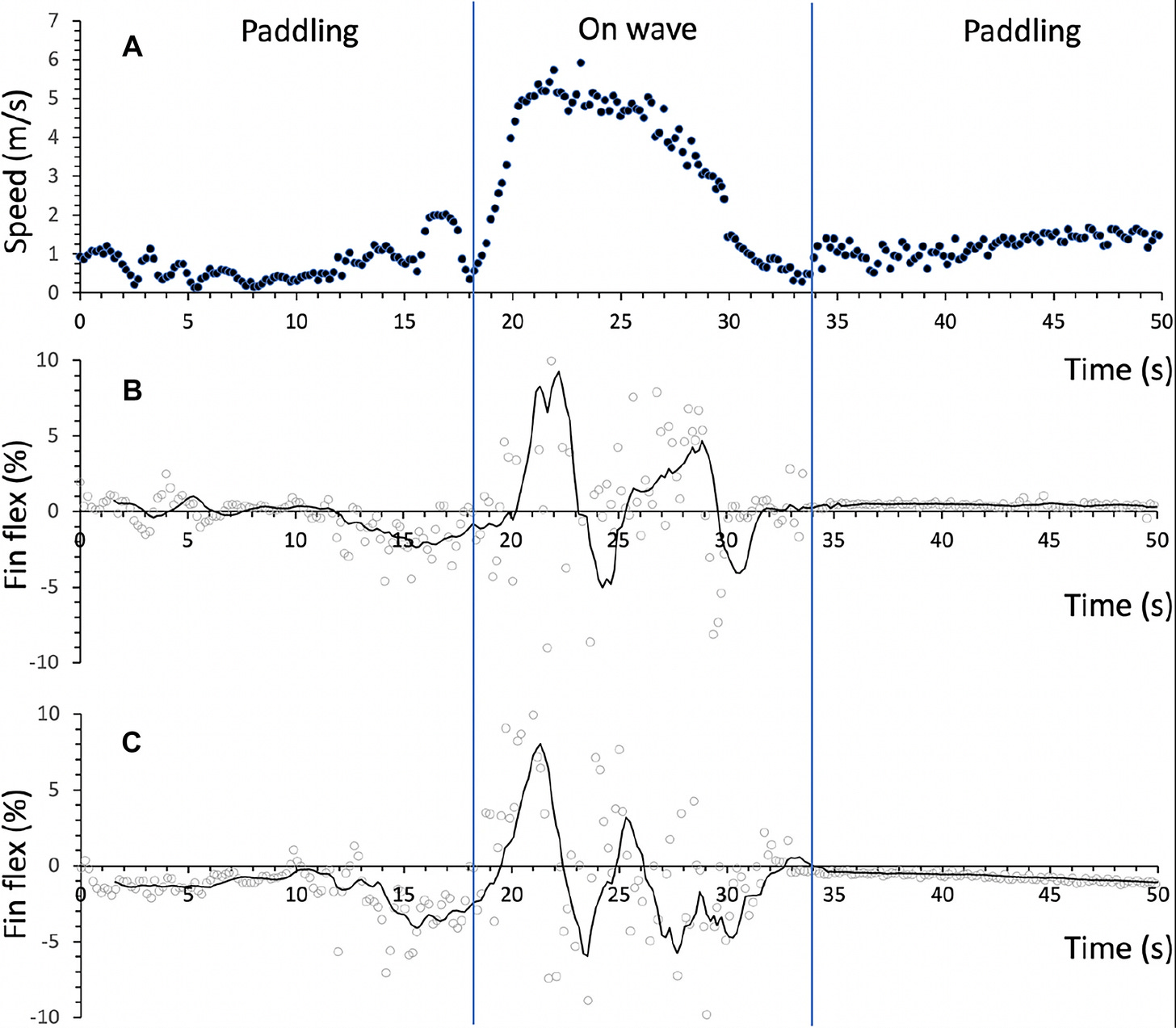

Jones Beach, Kiama Downs provided the testing grounds. The intermediate surfer (52 years, 83 kg) paddled out into 0.75-meter swell running at 12-second intervals. Over an hour and a half, he logged 13 waves. Not an epic day, but solid enough to generate meaningful data with an average of roughly 10 seconds per wave. The GPS tracked 570 meters of actual wave riding across 125 seconds of ride time, with speeds reaching up to 6 m/s. The instrumented fins recorded every bit of flex as the board carved through turns and sat idle between sets.

During paddling and waiting, both fins showed minimal flex, just 2-3%. At these low speeds, forces acting on the fins remained small, resulting in barely any deformation. But once the surfer caught a wave and initiated a bottom turn, the sensors spiked. Fin flex jumped to 8-9%, occasionally hitting 10%. This matches the German river wave study, which found approximately 70 pounds of force per fin during turns. The stiffness measurements from the lab (3.6 N/mm for the instrumented fins) combined with these flex values suggest the fins were experiencing loads in that same range.

On waves, both fins consistently flexed in the same perpendicular direction. The inside fin (closest to the wave face) bent inward toward the board’s center while the outside fin bent outward toward the rail. Maximum flex occurred during the initial bottom turn when speed peaked, then decreased gradually as the surfer moved through the rest of the wave. The fins loaded and unloaded in real-time as forces changed throughout each maneuver.

Lab tests and computational fluid dynamics have suggested how fins should behave under various loads. This study confirms what they actually do. The correlation between the 70-pound force measurements from the controlled river wave environment and the flex values measured here validates both approaches. The fins experienced exactly the loads the models predicted, deforming in response exactly as mechanical testing suggested.

The questions multiply from here. These 3D-printed fins are stiffer than most commercial fiberglass options, yet still flexed nearly 10% during hard turns. How would carbon fiber fins with half the flex respond? Could internal support structures reduce deformation without adding weight? And the bigger question that this study doesn’t address: is 10% flex at peak load beneficial for performance, or should we be designing fins that resist it entirely? Some argue flex adds drive through turns by storing and releasing energy while others claim stiff fins provide better control and response. The sensors can now measure the flex. Figuring out the optimal amount is the next challenge.

Further Reading:

I ride a quad, and after I lost the back two fins, I replaced them with the cheap plastic composite fins. The difference in flex and speed was huge, felt like a completely different board.